Table Of Content

The disadvantage is that large cows from breeds that have really wide bodies may have difficulty walking through them. V-shaped chutes work well for younger cattle handled in feedlots. Some commercially available one-way backstop gates are designed so that they can be opened easily and then held open.

Rope Corrals

Consider the you will use for the construction of the crowding tub. Ensure that the materials are strong and durable to withstand the pressure and weight of the animals. It should be large enough to accommodate the number of cattle you plan to work with. A larger diameter will provide more space for the animals to move around, reducing stress and preventing injuries. One of the key benefits of portable electric fencing is its versatility. It can be used to create temporary enclosures of various sizes and shapes, depending on the specific needs of the cattle.

Chain Link Fencing

Taking chutes and handling systems into the future - Ag Proud

Taking chutes and handling systems into the future.

Posted: Mon, 24 Feb 2020 08:00:00 GMT [source]

Where cattle flow easily through well designed pens and well positioned gates, one person can easily handle, and sort, a hundred or more cattle alone. The person working the crowd alley can walk directly across from the tub or box to the squeeze chute without stopping cattle flow. The squeeze chute is an essential part of any cattle handling system. It is designed to safely restrain the animal while providing access for various procedures such as vaccinations or hoof trimming. When constructing a DIY squeeze chute, there are several factors to consider.

Ranch (or Property) Designs

A backstop that pivots on the top can be easily rigged with a remote control rope. This enables a person who is located in the crowd pen area to hold the gate open for the animals. I have designed 11 new working facility layouts that can be easily constructed from portable panels and other premanufactured components.

Commercial Plant Facility Designs

It consists of horizontal wires attached to vertical posts, creating a grid-like pattern. The gaps between the wires can vary depending on the size of the cattle you are working with. It’s important to keep in mind that the holding capacity may vary depending on the purpose of the corral. For example, if the corral is primarily used for sorting or loading cattle onto trailers, a higher holding capacity may be required to accommodate the temporary increase in animal numbers. The holding capacity of the corral refers to the number of cattle it can accommodate at any given time. This capacity should be determined based on factors such as the size of your herd, the frequency of handling, and the duration of time the animals will spend in the corral.

Handling Equipment and Techniques

This information is then combined with the previous information on the area allowance per animal to determine the required pen size to hold a full cattle liner load of animals. Please note that the shipping numbers may vary from those shown. You may need to hold a pen full of cow-calf pairs prior to processing, and then have a pen available after processing for the calves you wish to send to auction. Both of these pens will have different requirements for the number of square feet per animal based on the different sizes of animals that will be held in the pens. Many commercially available single-file or double-file chutes are designed so that they can be adjusted for different size cattle. When shopping for chute sections, look for ones that are easy to adjust.

Panel corrals are typically made of sturdy such as steel or aluminum, ensuring durability and longevity. The panels are designed to interlock securely, providing a solid and secure enclosure for the cattle. Some panel designs even feature built-in gates, making it easier to move the animals in and out of the corral. Chain link fencing is a sturdy and long-lasting option for cattle corrals.

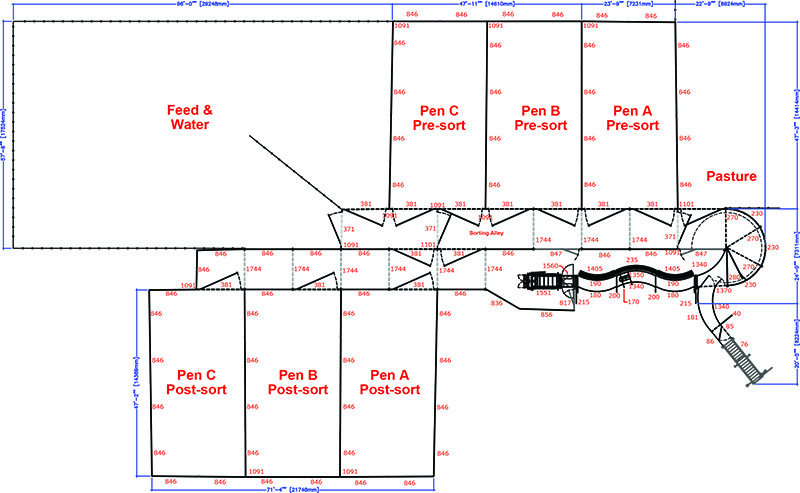

CAD Drawings of Cattle Corral Designs for Ranchers, Feedlots, and Meat Plants

Take time to describe, in detail, what you imagine your processing will look like when your facilities are completed. The images below show the load capacities for each section of a cattle liner.

Handling System Reviews

Because of our low overhead we are able to offer the most competitive prices and while continuing to use the best materials. At RCI each corral is fabricated by certified welders using the highest quality steel. RCI has been handcrafting custom corral panels in California since 2001 and is California’s most established corral builder. Because RCI exclusively uses Allied Gatorshield tubing with a 55KSI tensile strength rating, most of our original work remains in after years of use. Backed by an extensive 3-Year Warranty and a lifetime guarantee on latches, you can be confident in the product and know it will last no matter what you throw at it. "These plans are good and we will build many corrals of this model in Texas".

The dotted line shows the entry gate swing back in the correct position for cattle entry. The cattle enter the tub and then reverse and go back to where they came from. This system will work most efficiently if the single file race is almost empty BEFORE the cattle are put in the tub.

All catwalks are eliminated, and the inner fences are open on the top so that the handler can remain on the ground. Cattle equipment of any kind is an investment, and investing in a new cattle corral is a large one for any operation. Taking the time to truly plan out a beef cattle corral that will fit the needs of your operation while using low-quality components is a choice you may regret down the road. This diagram shows both the right and wrong layout for a curved race system. If the single file race is bent too sharply where it joins the crowd pen the cattle may refuse to enter because it looks like a dead end. Cattle standing in the round crowd pen must be able to see a minimum of three body lengths up the single file chute before the curve begins.

To reduce costs, catwalks along the sides of the single file chute have been eliminated. If you would like to learn more about how to create safe and efficient corrals you may consider visiting a local community pasture or livestock auction market. These facilities often have a wide range of well-designed corral features (You can also learn from observing what doesn't work; where animals are hesitating or becoming stressed).

Chute gates should be quick and easy to operate, without hindering movement on the catwalk. Sliding gates work well, but ‘gliding gates’ even better (gates that move like a sliding gate but smoother, and no runners to get in your way). A curved alley also saves steps for a person working both the crowd alley and squeeze chute. Gill feels that the curved crowd alley was adopted because people think cattle like to move in a circle. “The crowd alley is the chute leading from the Bud Box or tub to the squeeze chute,” Gill further explains.

PVC pipe is a versatile and cost-effective material that is commonly used for cattle corral construction. It offers several advantages, including its lightweight nature, resistance to corrosion, and easy maintenance. PVC pipe is also available in different sizes and can be easily cut and connected using PVC fittings. If, for example, you plan to ship 500 lb feeder cattle you can ship up to 108 head on a 53’ cattle liner. To hold this number in a short term corral pen you will need approximately 1,512 square feet of penning. If you need to hold these animals overnight you will need approximately 4,860 square feet of penning.

No comments:

Post a Comment